B1 BBQ

A barbeque designed for inclusivity and multicultural diversity.

Group Project Role: DFMA, CAD, BOM/Costings, Concept Development

Keywords: Sheet Metal, Design for Manufacture, Modular Design, Universal Design, Design Research

Background

Context

The Forest Lake Ward, situated in the southern regions of Brisbane, Australia is home to over 48,000 residents and is a community that prides itself on supporting residents from a multitude of backgrounds and cultures.

Consisting of a large population of Indigenous Australians, Vietnamese, Indian, South American and Pacific Islander communities, Forest Lake Ward’s dietary and cooking preferences along with their large social gathering requirements have been limited by the existing barbeque infrastructure.

Project Brief

To design a new barbeque for the Brisbane City Council (BCC) that accommodates the rich cultural diversity and meal preparation requirements represented in the Forest Lake Ward community.

Problems Identified From Research

Lack of precise temperature control

The cooking hotplate is too small

Central grease collection is not ideal

No open flame cooking options (doesn’t cater to all food types)

Water fixtures are located far away

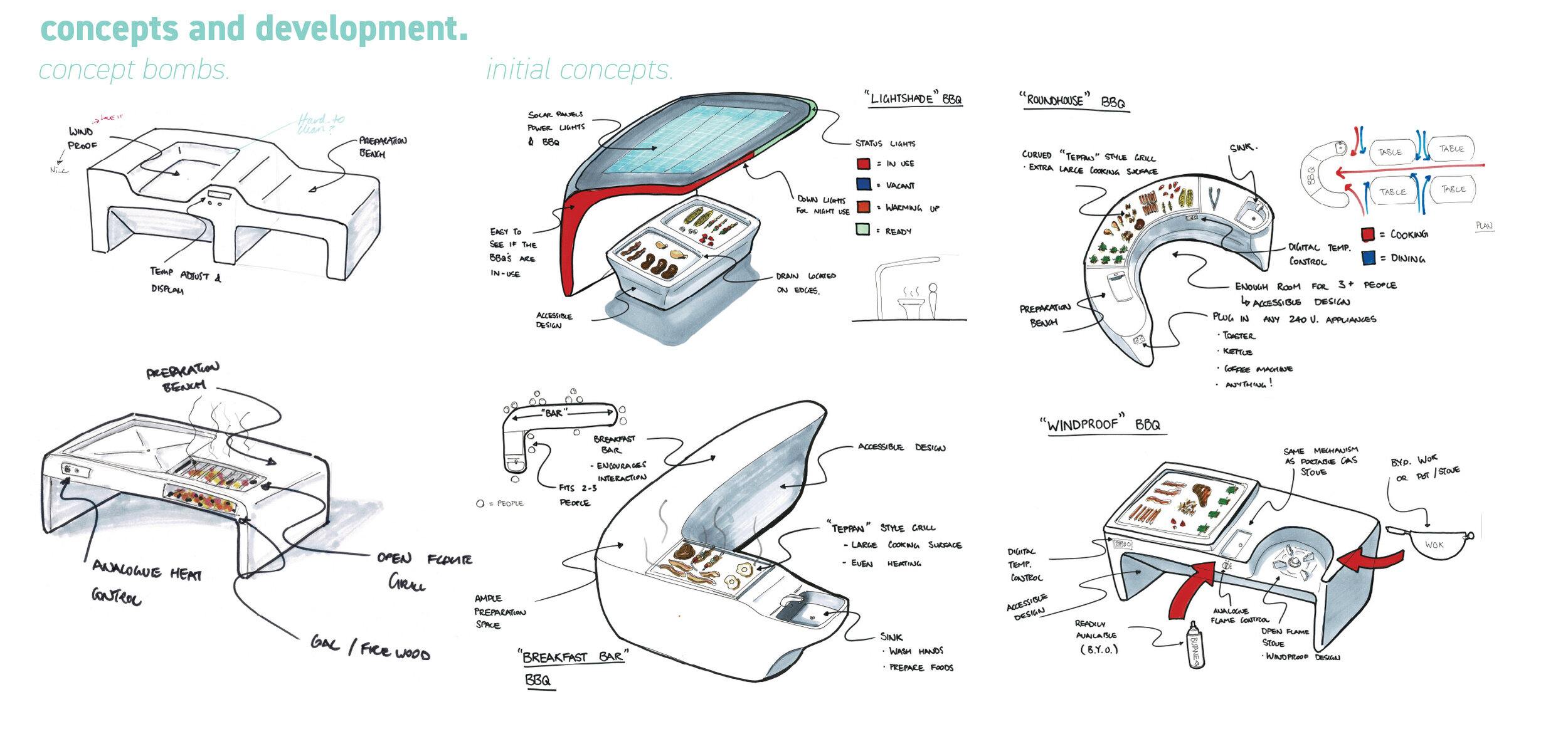

Initial Concept Generation

Initial concept generation was delegated to each team member to rapidly explore the different approaches to the design problem. Through the consultation with academic staff and the clients, selected elements were taken from the various initial concepts presented by the team and developed for further refinement.

Below is a sample of the initial concepts that I created in response to the design brief ranging from affordable to desirable.

Presenting:

The B1 Barbeque

Product Features

Universal Design for Universal Access

Standards

All functions and aspects of the B1 Barbeque have been meticulously designed for universal access which includes strict adherence and compliance to meet all relevant national standards.

This includes:

Disability Discrimination Act (DDA) 1992

AS1428.1-1992 (R2015) Design for access and mobility Enhanced and additional requirements - Buildings and facilities

AS/NZS3000:2018 wiring standards

Food Premises and Equipment Standard 3.2.3

Designed for Easy Assembly + Disassembly

Simple Construction = Simple Assembly

The internal 2mm SHS structural frame arrives prefabricated and allows for easy installation and removal.

Simply place and align the framework at the installation location and secure the frame with four anchor bolts.

Then, just attach all the other individual panels to the internal framework to complete the rest of the barbeque and drop in the desired modular components.

Drop-In Modular Components

Butane “Wok” Burner Module (Small)

The Butane Wok Burner Module allows for open-flame cooking that is familiar and intuitive to operate. Simply BYO butane canister and wok/frying pan, pop the canister into the socket and turn on the module to start cooking.

Hotplate Module (Large)

The hotplate module allows for precise temperature control from 75 - 275°C and features a larger cooking surface, a large and intuitive to use touch interface and a translucent lighting surround that notifies of the hotplates activity. As such, the hotplate module is able to accommodate a much larger variety of cooking requirements which completely transforms the public barbeque experience.

Sink Module (Small)

The sink module features a deep basin and a swivelling head with a proximity sensor that dispenses water automatically. This module ensures that the barbeques and other utensils can be cleaned effectively.

* In a standard configuration, the B1 features two hotplate modules, a sink module and a butane wok burner module.

Thoughtful Additions

Cooking Recommendations

With a heavy consideration for usability; language options, universal symbols, a redesigned user interface and ergonomic and access considerations are just some of the many details which have been meticulously designed to enhance the end-user experience.

Internal Structural Frame

Prefabricated 2mm Square Hollow Section

The internal 2mm SHS structural frame is loadbearing and provides a sturdy structure for all other parts to attach to.

In the case of transportation, the frame can also be used to winch the entire barbeque unit without any disassembly except for four bolts and be lifted onto a flatbed truck for easy removal or relocation.

Efficient Manufacturing

Nesting

All sheet metal parts have been designed for locally sourced and manufactured sheet metal.

With efficient nesting to ensure that there is minimal wastage of materials and that all parts can be flat-packed to reduce storage requirements and transportation costs.

Presentation Model

Process

Iterating through Making

Project Documentation

Specification Report

Product Brochure

Designed in Collaboration with:

Queensland University

of Technology

Christie Barbeque

Brisbane City Council